CNC Tundish Upper Nozzle

Overview CNC tundish upper nozzle Product Description This product is suitable for continuous cast tundish open cast ste

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | CNC |

| Workmanship | Casting |

| Insert Nozzle | Zro2 |

| Transport Package | Wooden Case |

| Trademark | XIAZHIMU |

| Origin | China |

| HS Code | 69029000 |

| Production Capacity | 50000ton/Year |

Product Description

CNC tundish upper nozzle

Product Description

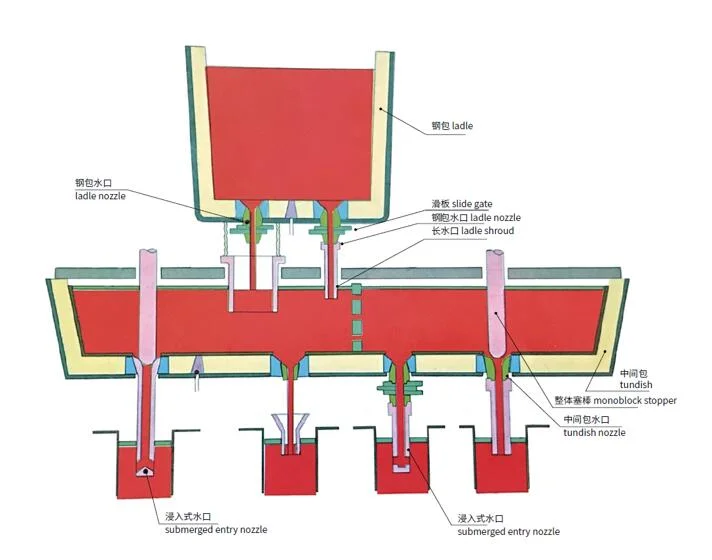

This product is suitable for continuous cast tundish open cast steel. The zirconium insert is made of high-purity zirconia, which is formed by high-pressure molding and sintering at high temperature. The outer is made of corundum and high-quality aluminum vanadium. It is formed by high pressure molding and baked at low temperature. The two are bonded with corundum mud, and the product's corrosion resistance and thermal shock stability have reached the domestic advanced level, which can fully meet the needs of various billet continuous casting. Tundish upper nozzle It is located within the tundish lining and conveys steel to the controlling exchangeable nozzle,which determines the steel flow. The stationary nozzle must be capable of withstanding long sequence times. Our Upper nozzle that incorporates a ultra-high densityLKZN-M or LKZN-H insert. The insert provides excellent erosion resistance and can provide extended casting sequence times. The lower surface of the stationary nozzle is ground to exacting tolerances to ensure maximum surface contact between the two nozzle components. Tundish lower nozzle It is located within an assembly that is fixed to the bottom of the tundish.The design of the exchangeable nozzle can vary according to the system manufacturer. We supplying a range of zirconia inserts and composite nozzle designs for the exchangeable metering of steel. Zirconia inserts can be supplied for on-site assembly into metallic holding blocks where cementing, grinding, size banding and on site drying are required prior to use. It was manufactured by both cast process of fine grained alumina method or presse process.

TUNDISH NOZZLE used for the continuous casting of steel.

Products used in Tundish can be offered to you as follow:Tundish metering nozzleNon swirling tundish nozzleTundish upper nozzleTundish lower nozzleTundish slide plateQuick-exchange tundish nozzleLadle shroudSubentry nozzle/ submerged entry nozzleMonoblock stopper

MNC tundish metering Nozzle changer

Features:

Highest safety in open casting process

Incresed yield of production with long sequence casting

Nozzle change or strand close less than one second

Quick start/stop of individual strand

Easy handling and operation results in a safe system operantion

Compact climenshions

Advanced mechanical system

Mechanical fixation of upper nozzle

Sliding drive arrangement-easy cylinder handling for nozzle change

Clear view to the nozzle & mold

Good access for nozzle tip cleaning

Spring well protected in housing against splashes and dirt

CNC TUNDISH NOZZLE

The CNC is the most user friendly and safe nozzle change device currently available for billet,bloom and beam casters.

Features;

Reduced tundish costs (refractory,manpower, energy)

Increased casting yield

Increase caster utilization

Improved operational safety

Refractory components:

Upper nozzle plate designed to avoid exposure to steel splashes

Refractory components available for open stream casting and alternative blank plate or double stroke.

Upper nozzle(Stationary nozzle)

It is located within the tundish lining and conveys steel to the controlling exchangeable nozzle,which determines the steel flow. The stationary nozzle must be capable of withstanding long sequence times.

Our Upper nozzle that incorporates a ultra-high densityLKZN-M or LKZN-H insert.The insert provides excellent erosion resistance and can provide extended casting sequence times.The lower surface of thestationary nozzle is ground to exacting tolerances to ensure maximum surface contact between the two nozzle components.

Lower Nozzle (EXCHANGABLE)

It is located within an assembly that is fixed to the bottom of the tundish.The design of the exchangeable nozzle can vary accordingto the system manufacturer.We supplying a range of zirconia inserts and composite nozzle designs for the exchangeable metering of steel.

Zirconia inserts can be supplied for on-site assembly into metallic holding blocks where cementing, grinding, size banding and on site drying are required prior to use.It was manufactured by both cast process of fine grained alumina method or presse process.Product Parameters

| Outer: Al2O3 | ||||

| Al2O3 | C | Apparent porosity | Bulk density | Compressive strength |

| (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 75 | 4 | 8 | 2.95 | 60 |

| 80 | 4 | 7 | 2.95 | 60 |

| 94 | - | 15 | 2.95 | 60 |

| Zirconia Insert of Tundish Upper Nozzle | ||||

| ZrO2+HFO2 | Apparent porosity | Bulk density | C.C.S | Refractoriness |

| (% minm) | (% max) | (gm./cc minm) | (MPa minm) | (ºC minm) |

| 65 | 23 | 3.60 | 80 | 1790 |

| 70 | 23 | 3.70 | 80 | 1790 |

| 80 | 23 | 3.90 | 80 | 1790 |

| 84 | 23 | 4.00 | 80 | 1790 |

| 93 | 21 | 4.50 | 100 | 1790 |

| 94 | 21 | 4.90 | 100 | 1790 |

International standard seaworthy exportable packing.1. Wooden case (Seaworthy standard packing)2. Further packing information based on customer's requirements

The tundish metering nozzle is mainly used for continuous casting of tundish billets, blooms, rectangular billets, and small slabs for pouring steel.